Home

About Us

Solutions

- Scaling, Plugging & Grit Removal

- Reactivity &

Consistency

- Materials,

Equipment, Energy & Transportation Costs

-

Environmental Problems

Applications

- Water

& Wastewater Treatment

- Flue Gas

Desulfurization

- Caustic

Replacement

- Mining

-Construction

Uses

Case Studies

Services

Contact Us

|

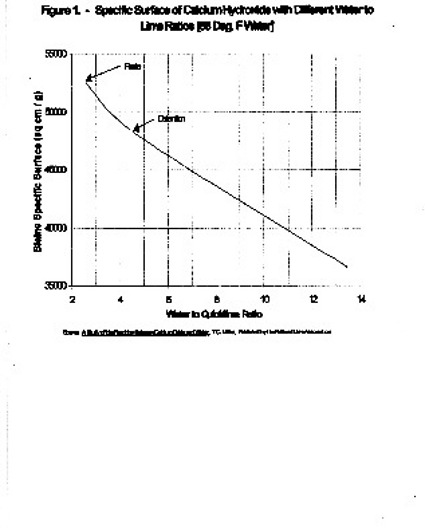

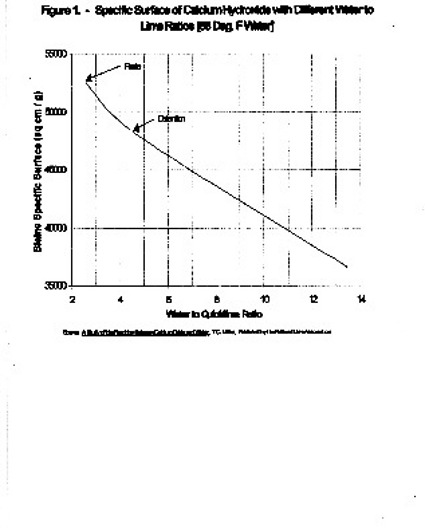

The amount of usage of hydrated lime slurry is

largely dependent upon its

reactivity. The National Lime Association has published a

chart showing that as the water

to quicklime ratio decreases, the surface area of lime particles

increases. Since the Lime-Save

process (USPTO patent #7,718,085 & #7,897,062) allows for solids content well above

40%, less water is required to

slake the quicklime than normal operations. It follows that

hydrated lime slurry made from the Process would have higher than normal surface area.

Since surface area is a predictor of reactivity, it is assumed

that is at least part of the reason of the success of the Process at

the power plant near Phoenix Arizona resulted in a 38% saving in lime usage compared with

what was expected.

Batch processing allows the

amount of water to be used

to make the batch to be metered

into the mixing tank in relation to the known weight of the quicklime to

be slaked. After initial slaking, the slurry can be tested by a

simple method to make any further additions of water to result in a

consistent lime slurry product. |

Typical

Slurry

Analysis

National

Lime Association Chart

Bromatco, LLC

Phone: (602) 758-2815

Fax: (602) 391-2258

|